WHAT'S NEW

What's New

23 Dec, 2019

Every year, Comtek runs a Holiday Food Drive to help support families in need in our local communities. Between the company and it's employees, Comtek raised $9,350 worth of food donations for Hamilton Food Share, a local charity that takes healthy and good product deemed surplus and un-salable by food industry standards and redirects it onto the tables of the people who need it the most. Learn more about the charity at the Hamilton Food Share website - www.hamiltonfoodshare.org . Season's greetings and have a safe and prosperous New Year!

12 Nov, 2019

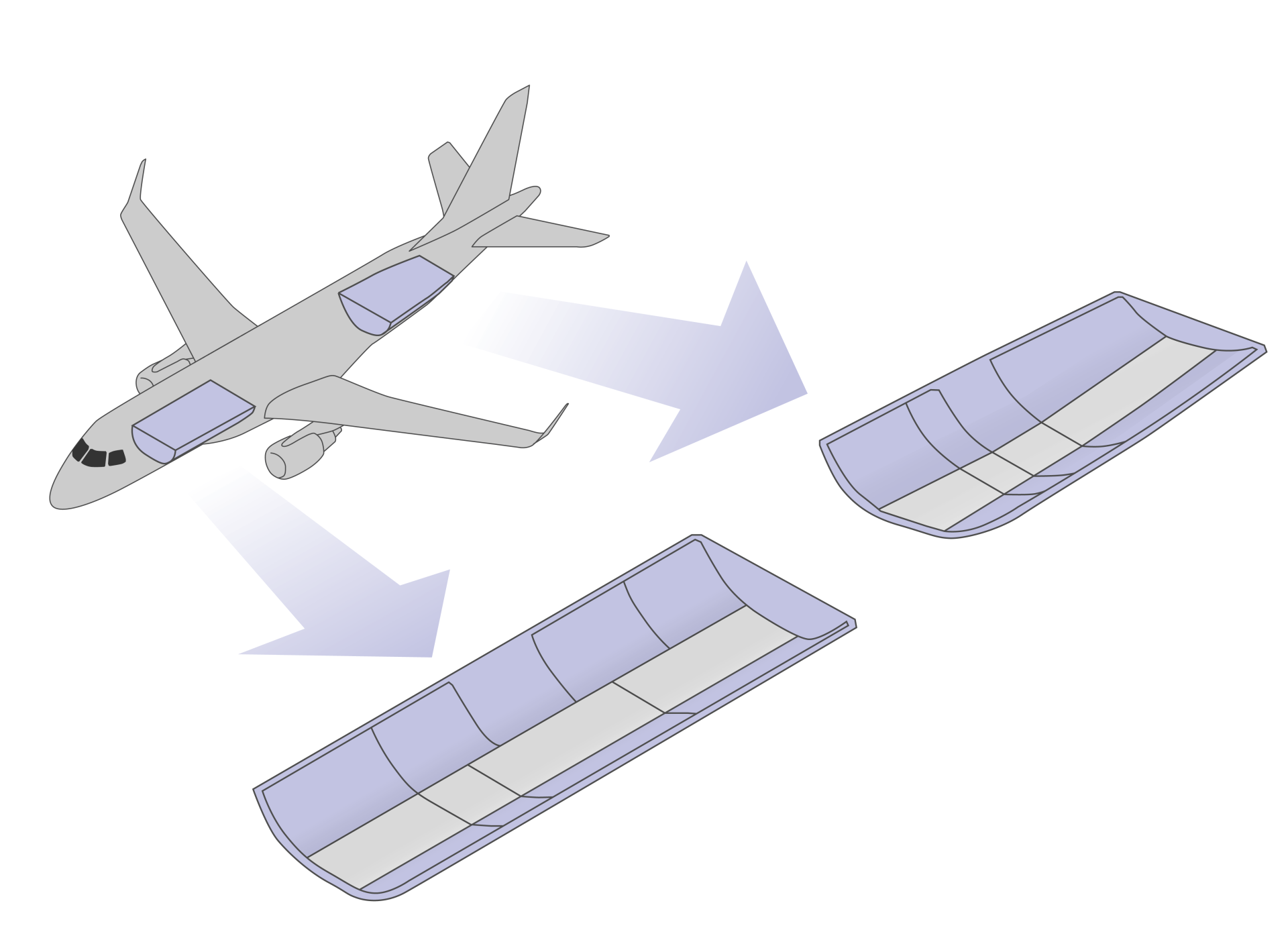

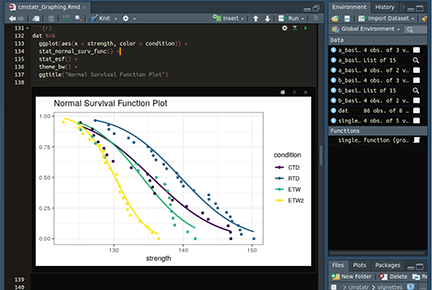

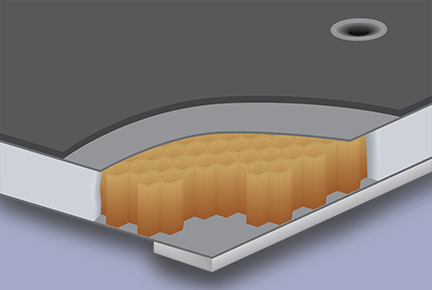

Aircraft floor panels have an important role in more than simply providing a flat surface to walk on. They are a component of the aircraft structure, which means they play a role in the overall safety of an aircraft during normal operations, emergency landings and rapid decompression events. Modern panels may also include additional functionality that can provide benefits in conductivity and cabin configuration versatility.

By Comtek

•

27 Mar, 2018

We have launched a new website with the aim of providing a more complete presentation of who we are and the solutions we provide our customers. Since we are involved in different levels of the aerospace value chain with each segment having distinct needs, we find that an awareness of all the products and services we provide is seldom complete. We have rearranged the site's structure with this in mind to help visitors understand Comtek's business and the unique range of services we provide across business jet, regional aircraft and aero-engine markets. In a nutshell, we: Supply aircraft OEMs with composite component design and manufacturing services: Composite panels Engine components Support fleet operators and MROs with component repairs and replacement parts: Structural component repairs Aftermarket floor panels

By Comtek

•

23 Jul, 2014

We are pleased to announce that Comtek has received AS9110, Revision B certification. Formally titled “AS9110 Quality Maintenance Systems ‐ Aerospace ‐ Requirements for Maintenance Organizations”, AS9110 provides the same level of control and customer confidence for Comtek’s repair customers as AS9100 provides to customers of Comtek’s manufactured products. “Ensuring customer confidence is vital to Comtek’s culture of building successful long‐term relationships”, states Spencer Warren, Quality Assurance Manager at Comtek. “By improving our quality management system to meet AS9110 we are exhibiting our commitment to provide repair services at the highest level of satisfaction while also minimizing our customers’ need to manage risk as trained, professional auditors are checking our performance.” This certification has elevated Comtek's Approved Maintenance Organization (AMO) to the global standard established by the International Aerospace Quality Group (IAQG) for the aerospace industry. Learn more about Comtek's quality approvals .

By Comtek

•

06 Jan, 2014

We are pleased to announce Comtek has been awarded a contract to design and manufacture the floor panels on Bombardier Aerospace’s* Global* 7000* and Global 8000* aircraft. Comtek will commence design engineering in early 2014. “Comtek is pleased to continue its support of Bombardier through the Global 7000 and Global 8000 aircraft programs”, states Brent Collver, President of Comtek, “It is Comtek’s culture to continuously innovate and deliver the highest performing products to our customers. This culture is at the core of our long-standing relationship with Bombardier and we are excited to expand it further into Bombardier’s premier business jet segment”. Comtek currently supplies floor panels to Bombardier Aerospace for the CRJ700*, CRJ900*, CRJ1000*, and Q400* aircraft and also provides aftermarket supply to aircraft operators. * Trademarks of Bombardier Inc. or its subsidiaries.

By Comtek

•

26 Jun, 2013

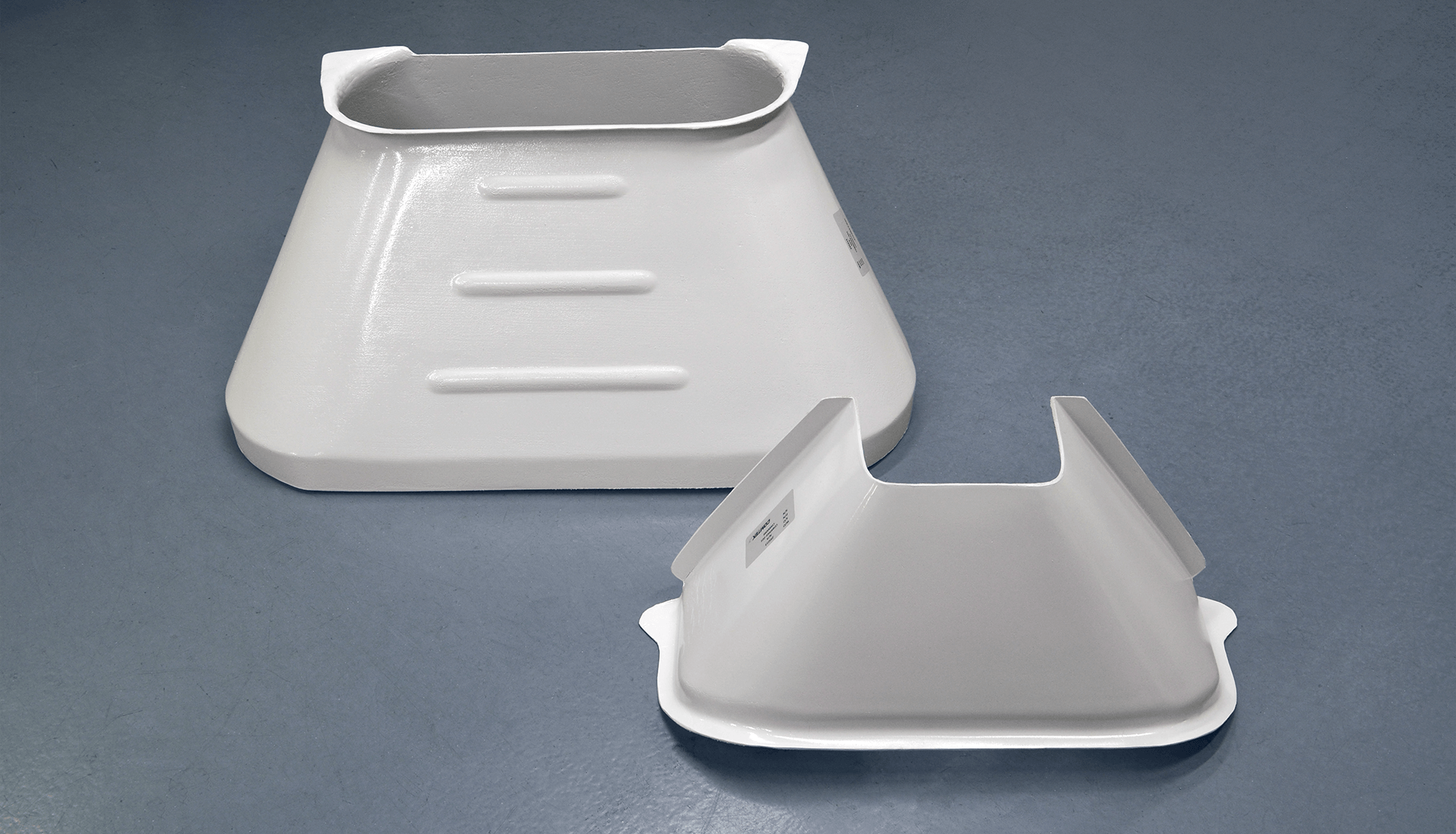

Comtek has received PDA design approval from Transport Canada on the Embraer 170/190 cabin & baggage floors, allowing Comtek to develop aftermarket floors for this aircraft. Under the existing bi-lateral agreements, this PDA approval is accepted under FAA and EASA airworthiness rules. This approval allows Comtek to leverage its extensive experience in the design and manufacturing of floor panels on other aircraft platforms to sell a cost competitive product directly to Embraer operators with improved lead times over OEM. The floor panels are constructed to be highly wear resistant for maximum durability and are guaranteed by a 2 year warranty that covers materials and workmanship. Comtek will continue to expand the list of available part numbers based on customer demand until such time as the 170 and 190 platform portfolios are complete. Learn more about our E-Jet Floors .

By Comtek

•

17 May, 2013

As a continuous improvement initiative, Comtek has rolled the production of the CRJ200 aftermarket floor panels into the OEM production line resulting in an immediate price reduction for customers. A streamlined approach to the construction of the product has successfully increased overall efficiencies while maintaining the same high quality standard. By combining the two production lines, our improved process has allowed us to capture the efficiencies and economies of scale associated with full production rates. This results in better pricing for our CRJ200 floor panels. The CRJ200 aftermarket floor panel line encompasses the complete set of CRJ200 cabin and cargo area floors. Comtek will continue to offer the same product with heavy-wear resistance for maximum durability and a 2-year warranty that covers materials and workmanship. The product is delivered ready to install and requires no aircraft modifications. Learn more about our CRJ floor panels .

By Comtek

•

10 Apr, 2013

Comtek Advanced Structures proudly sponsors the University of Western Ontario Aero Design team to support their efforts in the SAE Aero Design competition on March 15th to 17th in Fort Worth, Texas. The Aero Design team, an undergraduate engineering student run club, will be entering two classes of the competition with their “advanced class” and “micro class” aircraft. The objective of the advanced class design is to build an aircraft powered by a nitro engine capable of dropping a three pound humanitarian aid package from a distance of 100ft. The objective of the micro class is to design and build an aircraft powered by an electric motor that can take off and land with the heaviest payload. The U of W team will manage the entire project by researching, analyzing, designing, constructing and testing the aircraft to get it ready for the competition. Comtek’s involvement will include CNC machining to produce the fuselage foam core piece of the aircraft based on CAD drawings from the team and will provide guidance and on-site support throughout the project. “The Aero Design Team consists of a group of smart, enthusiastic and elite engineering students and we are happy to provide the team with practical skills that aren’t necessarily available in the classroom”, says Charlene Ridley, Product Line Manager at Comtek. In exchange for their support, Comtek will have the satisfaction of helping a motivated team of engineering students and seeing the company logo proudly displayed on the body of the aircraft.

By Comtek

•

01 Oct, 2012

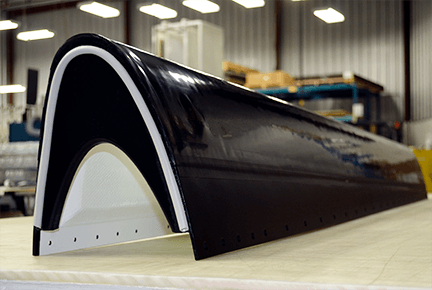

We have added repair capabilities for the Q400 lower cowl including the acoustic liner and the modification of the L/H and R/H lower cowls to give interchangeability. The acoustic liner repair capability is in direct response to the large number of acoustic liners that are being damaged from heat, air flow, moisture and foreign object debris (FOD). Comtek’s repair capabilities offer a unique solution that not only saves the aircraft operator a significant amount of time and money but allows for the acoustic liner repair to take place without removing the intake. In addition, the local repair maintains the part shape, doesn’t change the acoustic liner properties, does not block the drain channels in the OEM part or hold moisture. The Comtek acoustic liner repair offers a unique solution to a common problem.

By Comtek

•

07 Aug, 2012

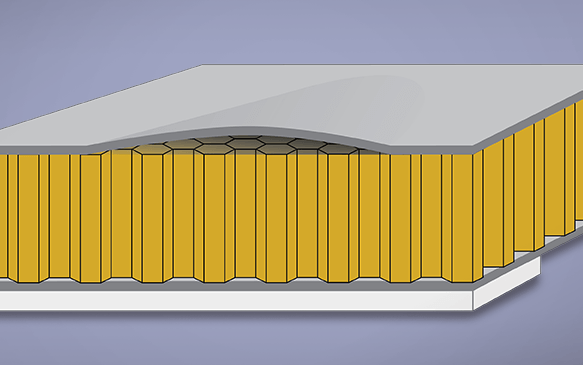

Comtek Advanced Structures has developed several floor upgrade packages for the Bombardier Dash 8 Q400 aircraft. The floor upgrade packages are available for the forward entry, aft entry and the aft upper baggage bay. Due to high levels of traffic and stress during regular use, the floor panels in these areas need to be replaced or repaired frequently. Comtek developed floor panel upgrades using more robust materials such as heavy duty honeycomb core to increase stiffness and durability and a mat overlay to reduce surface wear and increase impact resistance. These upgrades will give operators an increased operational life on each of the panels by improving the reliability of the aircraft with respect to these areas. Each floor upgrade package comes with a 24 month warranty on materials and workmanship. Learn more about Comtek's Q400 floor panels .

By Comtek

•

01 Jun, 2012

AMOC repair scheme for the CRJ700/900 Transcowl fixes problems highlighted by TCCA AD: CF-2009-33 and FAA AD: 2011-17-12

By Comtek

•

01 Apr, 2012

AMOC repair scheme for the CRJ700/900 Transcowl fixes problems highlighted by TCCA AD: CF-2009-33 and FAA AD: 2011-17-12

Comtek designs, manufactures and repairs aircraft components with a focus on improved durability and shorter lead times. Using advanced out-of-autoclave technologies, we develop composite solutions that reduce part weight, lower total costs, and shorten production cycles.