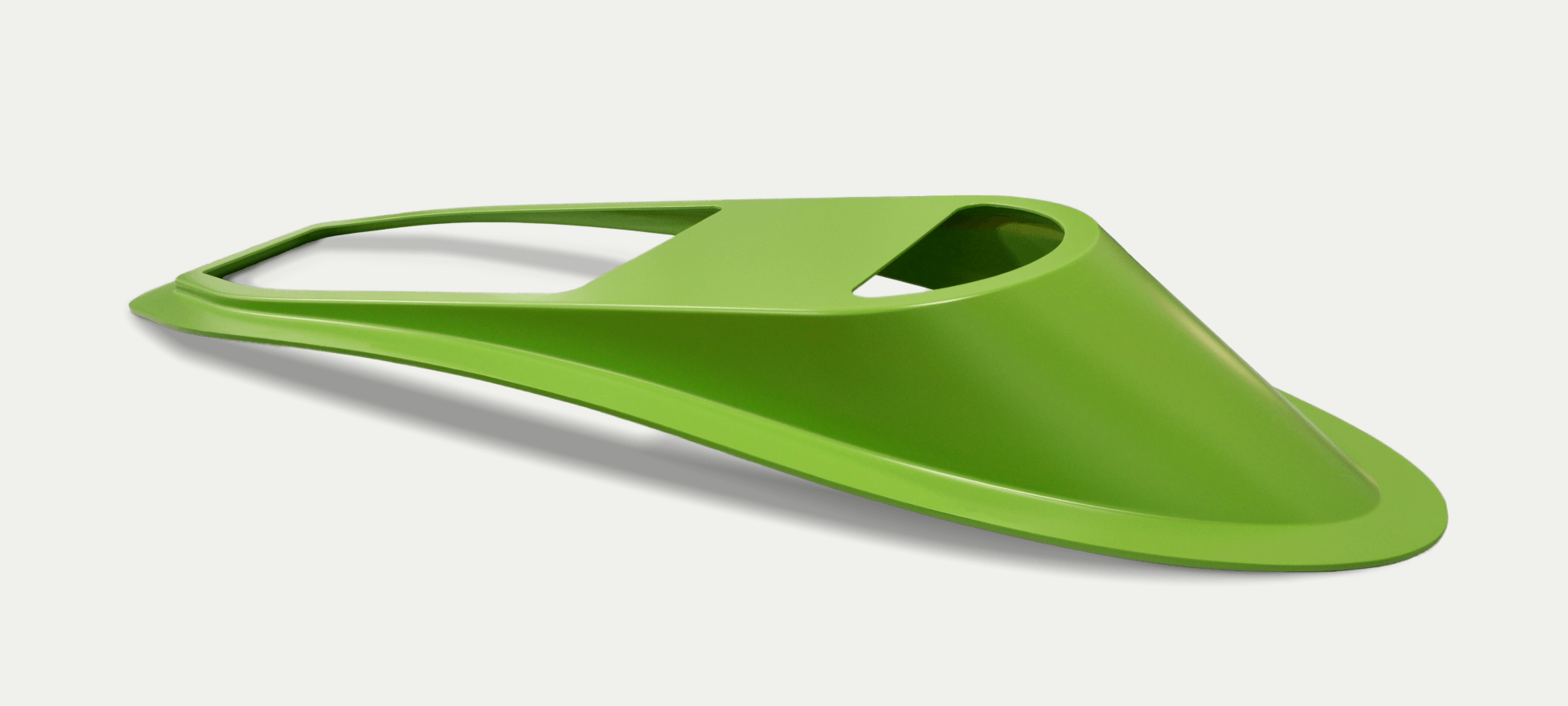

Comtek Delivers One-Off Composite Part to Support Customer Fleet

July 8, 2020

Recently, one of Comtek’s customers needed a fairing built for newly converted aircraft that matched an existing component on their in-service airplanes. Comtek had designed and manufactured the original fairing but due to the age of the design, recertification was now required because of material obsolescence. The customer no longer had tooling or a model for the part, and also requested alterations to the part so a full-scope solution was required. Comtek’s Engineering team started from a set of dimensional and structural requirements from the customer, then designed the shape, selected materials and lay-up configuration, made structural analyses, and completed the certification process with Transport Canada.

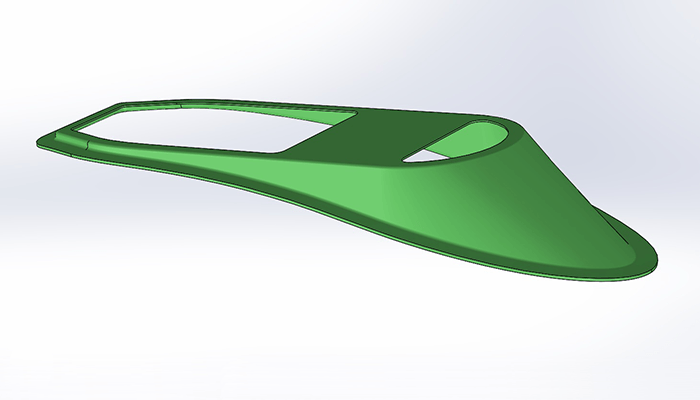

Comtek visited the customer’s site to perform an outer mold line scan of the existing part installed on one of the in-service aircraft. A 3D Measurement Device (CMM FaroArm) was used to measure the part details. The data collected was brought back to Comtek’s Engineering team in Burlington, Ontario and then used to develop a precise CAD model of the fairing. Using this model, and under our guidance and supervision, we tasked one of our tooling contractors to produce a carbon-fiber lay-up tool. We used this tool in one of our Out-of-Autoclave (OOA) composite part fabrication cells to produce a new glass-Kevlar fiber prepreg part. The use of OOA technologies keeps tooling costs down, removes the added expense associated with an autoclave, and shortens the overall production time. The production cell is comprised of a ply cutter room, clean room for lay-up, oven for cure, trim and drill, CMM Inspection, and then prime and paint.

Comtek Engineer Taking On-Aircraft Measurements

CAD Model Developed from CMM Data

Low Cost Tool Produced for Composite Part Lay-up

Whether our customers require hundreds of parts on an OEM program or a one-off to match an existing part, we are committed to developing solutions for all customer needs, regardless of scope. We take enormous pride in our know-how and efficiency to produce aerospace quality composite parts. We have the ability to produce virtually any composite component quickly and cost-effectively thanks to our knowledgeable engineering team, our established facility resources, and our proven OOA technologies.