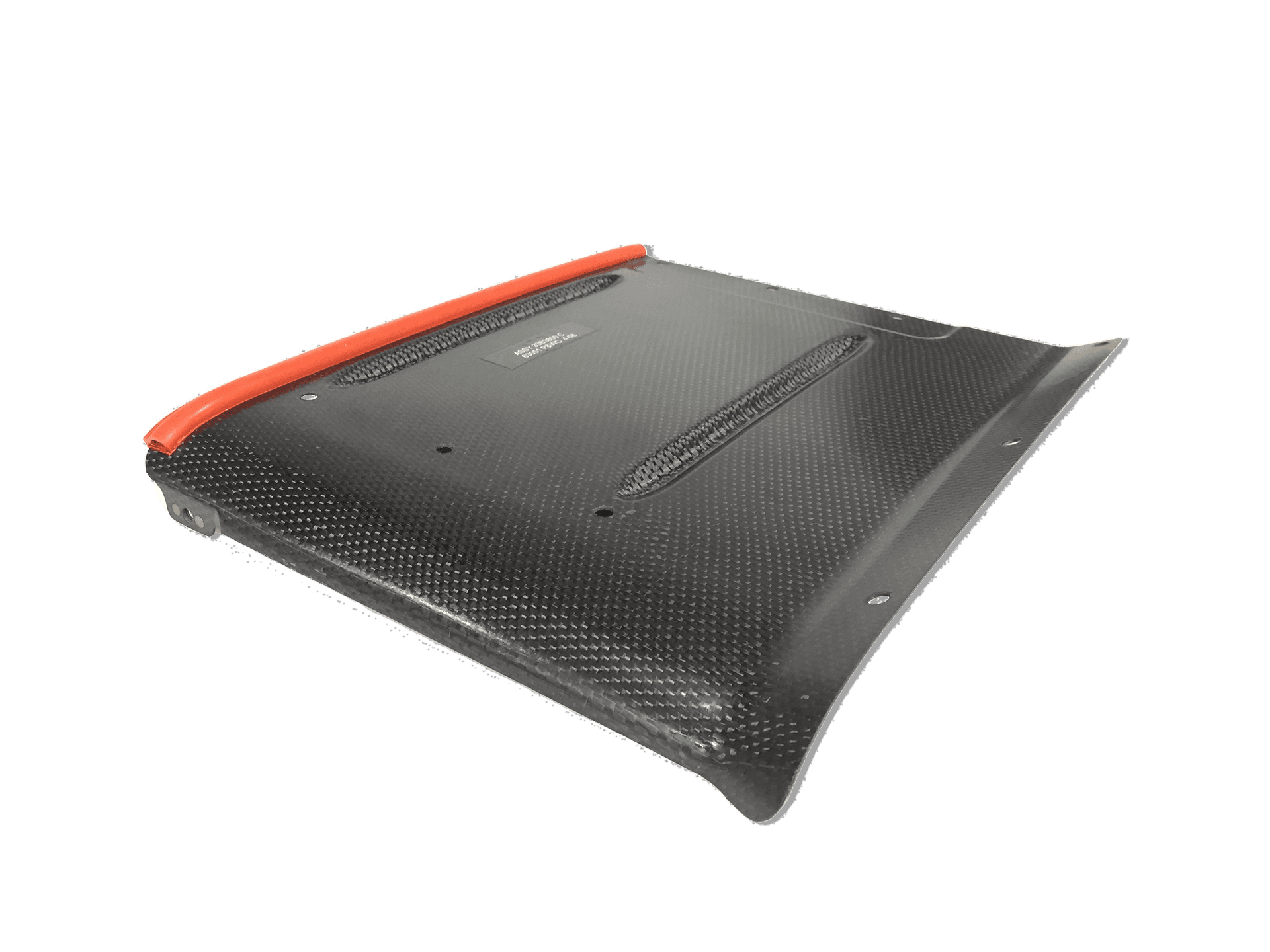

Thin Shell Aero-Engine Composites

Material, design and process development for unique and challenging applications

Unique Challenges

Full Scope of Services

Proven Track Record

Using advanced out-of-autoclave technologies that we have developed and refined over the past 25 years, we design parts and fabrication solutions for challenging requirements with the agility to manage tight timelines.

Through close relationships with raw materials suppliers and ongoing research by our R&D materials team, we have extensive materials knowledge that we harness to overcome complex issues. Composite assemblies with challenging operational environments require unique solutions. These conditions can cause constraints with economic viability, limiting the advancement of composite applications. Comtek employs a range of proprietary processes that enables a wider variety of processes, part complexity and production volumes to be produced cost effectively. We can specify materials and designs for harsh operating environments where conditions like continuous heat and abrasion have traditionally limited available material options to metals. With our experience, we can quickly tailor processes to produce optimized parts using the right materials.

We have a unique combination of approach and capabilities that allow us to develop solutions in design, fabrication, and certification processes. Our vast materials and production expertise allows us to develop lean production processes with rapid production cycles that ensure cost competitive solutions are delivered to market.

We are an agile partner, collaborating fully with our customers through design iterations and tailoring solutions in real time for the best possible commercial and technical outcomes. For customers requiring a more turnkey approach, we can take projects through to completion independently provided with scope and design parameters.